Ball Mill Ball Mill For Powder Making Service Provider ...

Service Provider of Ball Mill Ball Mill For Powder Making offered by Geneva Design Solutions, Pune, Marashtra.

WhatsApp)

WhatsApp)

Service Provider of Ball Mill Ball Mill For Powder Making offered by Geneva Design Solutions, Pune, Marashtra.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Home Page > Powder Slurry Mill / Mixer MTI has been manufacturing laboratory mill/mixer since 1994, offered the first model of ball mill into the world. Then the following years we''ve been devoting ourselves to designing the most efficient, practical and affordable laboratory mill/mixer. Thus ...

Nov 14, 2012· In this video I feature the ball I just made with misc material I had laying around the house and shed. During the time it took to edit and post this video I ran the charcoal through the mill and ...

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ratio for ballmilling a new material? ... of 67 for ductile powders when using ...

Full Directional Rotation Lab Scale Micron Fine Milling Powder Grinding Ball Mill; Cooling Air Controlled Nano Powder Making Laboratory Type Cryogenic Grinder; Industrial Nano Powder Planetary Ball Mill for Production; 50ml*4 Jars Small Planetary Ball Mill; Laboratory Horizontal Planetary Ball Mill for Powder Making; Fine Grinding Equipment ...

Ball mills are also used for the particle size reduction of black powder, cement, fertilizer, silicates and even a variety of ferrous and nonferrous metals. Ball mills are very similar in design and operating concept to rock tumblers, which used milling media to polish rocks in a rotating cylinder.

How to decrease particle size of alumina powder with ball milling? ... I applied ball mill for 24 hour and dried it for about 16 hour in oven at 105 celsius degree. ... milling again. should I add ...

3. When you open your mill, you should find an incredibly fine black/greyish powder. Sieve this to get the media of the mill out, and weigh it. In a separate container, place 75 grams of potassium nitrate for every 25 grams of charcoal/sulfur powder you have. Put the potassium nitrate in your ball mill, and mill it .

Your source for the best grinding and milling equipment. We have the most advanced grain mills, powder mixers, ball mills, sieve shakers, and pulverizers.

M. Ramezani, T. Neitzert, Mechanical milling of aluminum powder using planetary ball milling process, Journal of Achievements in Materials and Manufacturing Engineering 55/2 (2012) 790798. 1. Introduction Mechanical alloying (MA) is a high energy ball milling process by which constituent powders are repeatedly deformed,

Nov 14, 2015· Please subscribe! Thank you for watching! I wanted to see if I had any 500 mesh (less than 25 micron) size aluminum powder in the ball mill yet. So I processed some of what what was in the mill ...

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help.

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill. ... Salili et al. reported the importance of the small ball size and small mass ratio of powder to ball for the efficient ball mill, while only two sets of experimental data for these variables were provided. Thus, the optimization of ball size ...

What is Ball Milling? Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber.

Powder Processing Technology, LLC provides the equipment, facility and manpower for complete powder toll processing including wet grinding, toll milling and toll classification. We have the ability to pelletize powders, mill down pellets to powders, mill powders down to µm in size, and batch and blend various sized powder quantities.

Dec 11, 2015· 6lb Black Powder Ball Mill Heavy duty rubber drum is sparkproof and leakproof. 110v,

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals, and glass ceramic industry.

Powder Processing with Milling Media. At MSE Supplies, we are experts at powder processing materials, ball milling equipment and accessories. When it comes to grinding media, our most popular materials include zirconia and alumina. You''ll also find materials including tungsten carbide, stainless steel .

Lloyds''s book is the most complete and practical resource I know for information on ball milling theory and for plans to actually build your own ball mill. Here''s a shot of a nice, doublebarrel mill I built based on his principles. Homemade DoubleBarrel Ball Mill Ball milling replaces potentially unsafe hand grinding of chemicals and ...

To mix the black powder ingredients together, open your ball mill (rock tumbler) and add the three ingredients and the lead balls. As the tumbler rotates, the balls will crush the chemicals together and grind them into a powder. The longer you let the tumbler run, the more finely ground the black powder .

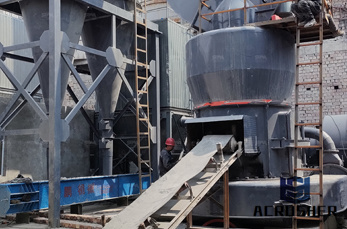

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

Milling of bulk solids and powder. common mills, selection of mills and safety of powder milling equipment. Menu access Engineering Resources Solids properties and flow Unit operations Equipment Handbook Mixing ... Mills with size reduction media: Ball mills (dry)

Jul 20, 2019· The small and average capacity Ball mills are used for the final grinding of drugs or for grinding suspensions. The maximum capacity Ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals. Advantages of Ball Mills It produces very fine powder (particle size less than or equal to 10 microns).

WhatsApp)

WhatsApp)