Cement hydration Understanding Cement

Storage and Handling of Cement and Aggregates

WhatsApp)

WhatsApp)

Storage and Handling of Cement and Aggregates

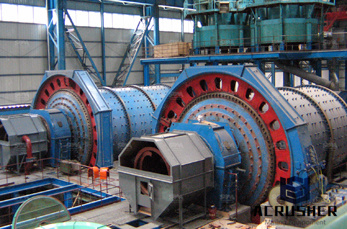

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

At Powder ProcessSolutions, we specialize in properly designing and configuring storage silos and hoppers specifically for the food, dairy, and nutritional industries. At Powder ProcessSolutions, we specialize in properly designing and configuring storage silos and hoppers specifically for the food, dairy, and nutritional industries.

Nov 20, 2017· Firstly clear that from which condition you want to store the cement like: * if you are owner and sell cement in that condition * if you are doing construction work. * if you are in labor . These are the different things. Because in these conditio...

Guidelines for storage and handling Blupe Steel''s products. ... an input into the customers'' risk assessment process for storage and handling of coil, plate, sheet and long products ... Prerequisites for Safe Storage Guidelines for storage and handling Blupe Steel''s products 4. Prerequisites for Safe Storage ...

Aug 07, 2008· Cement from CO 2: A Concrete Cure for Global Warming?. A new technique could turn cement from a source of climate changing greenhouse gases into a way to remove them from the air

Sep 22, 2016· However, if the cement particles are too small, it is easy for them to react with the water and the calcium dioxide in the air to destroy the storage of cement. If the cement is too fine, its shrinkage is large in the hardening process. Thus, the finer the cement is ground, the more energy will lose and the higher the cost will be.

May 29, 2010· Cement may also be delivered in bottomdump trailers that use gravity to move the cement. Other options include screw conveyors and bucket elevators. Cement is generally moved from the truck and into the storage silo using one or more of these transport systems.

While it is true that covering the curing concrete with plastic will keep it cleaner, there is a more essential purpose behind this practice: Remember, you mix water into concrete to activate the cement binding agent within. As the mix dries, it will harden. But the drying, or "curing," should be gradual, otherwise cracking may occur.

STANDARD OPERATING PROCEDURE FOR STORES FUNCTION AT NAC AND ITS CONSTITUENT UNITS, NAC ... Storage is an essential part of the economic cycle and Stores Management is today a ... cement, food, etc. The oldest stock has to be issued first.

Thermal energy storage (TES) is achieved with widely differing on the specific technology, it allows excess thermal energy to be stored and used hours, days, or months later, at scales ranging from the individual process, building, multiuserbuilding, district, town, or region. Usage examples are the balancing of energy demand between daytime and nighttime, storing ...

THE CEMENT MANUFACTURING PROCESS quarry raw grinding and burning grinding, storage, packing, dispatch HOW TO USE THIS PRESENTATION : > once the animation has finished, click anywhere on the screen to move on > click on « next » to see the next stage of the cement manufacturing process Click here to start THE CEMENT MANUFACTURING PROCESS 1.

6 Best Practices Guidelines for Concrete Construction Once the concrete supplier is aware that a specific general contractor or construction manager has expressed interest in obtaining quotations for concrete supply, they should contact the estimator or manager in .

Quality Management System for Ready Mixed Concrete Companies Parts A and B prepared by: William C. Twitty, Jr., Part C Developed by the NRMCA P2P Steering Committee Reviewed and Approved by the NRMCA P2P Steering Committee

Water storage tanks, also known as cisterns, are primarily used to store water for domestic and consumptive purposes in s or buildings. Cisterns are typically found in areas where a potable water source is not available in the community, the area yields low well water capacity, or the groundwater quality is poor.

Batching, Mixing, Transporting, and Handling Concrete. setting becomes a persistent problem, a retarder may be used to control early hydration, especially in highcementcontent mixes. Mixture adjustments at the jobsite for air entrainment, and the addition of other admixtures, is permitted, followed by sufficient mixing.

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Sep 17, 2015· 15 Cement Storage Silo The cement storage silo is used for storing the finished product – cement. 16 Packing and Dispatch The cement is packed with the help of a rotary packer and finally dispatched to the market. 15. 17 Central Control Room It is the nerve center of the cement plant since all equipment is controlled from this place.

Feb 16, 2016· A stacker reclaimer for Limestone storage is shown in the video in a cement plant. Stackers and reclaimers are used in stockyards to stack minerals, ore, and other granular raw materials in ...

batched or prepared at a building construction site. Figure is a generalized process diagram for concrete batching. The raw materials can be delivered to a plant by rail, truck or barge. The cement is transferred to elevated storage silos pneumatically or by bucket elevator. The sand and coarse

Portland Cement . Cement: is a material with adhesive and cohesive properties which make ... pumped into storage tanks. From here onwards, the process is the same regardless of the original nature of the raw materials. The slurry . is a liquid of creamy consistency, with water content of

Permanent Cement Storage Silo and Portable Cement Silo. The height and volume of cement storage silo vary according to different storage requirements. In real world application, the cement storage silo can be structured to hold no more than a few tons of dry cement production, or be designed to efficiently hold several hundred tons.

Heavy containers of cement shall not be stacked more than two tiers high. Cement shall be used in the order they are received; storage shall facilitate this requirement. Hooks shall not be used for handling cement bags unless permitted by the supervisor. Workers handling cement shall put on protective hand and face coverings and use skin ...

Storage of aggregates, cement, PFA and admixtures in silos, bins and hoppers is often considered the first part of the concrete production process. It is also the first area in which we can apply our expertise to solve a number of challenges, helping to optimise this part of the process.

WhatsApp)

WhatsApp)