Vertical Mill Drills | Baileigh Industrial

Baileigh Industrial offers metal machinery and metal fabrication equipment. Look no further than Baileigh Industrial for you Fabricating Needs.

WhatsApp)

WhatsApp)

Baileigh Industrial offers metal machinery and metal fabrication equipment. Look no further than Baileigh Industrial for you Fabricating Needs.

East alabama farm equipment and livestock has 1,513 members. this group is for buying and selling farm equipment and livestock. Buy and Sell Group

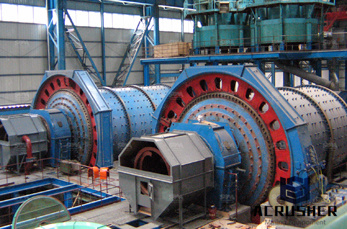

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Figure Diagrammatic representation of a mechanical stone mill with vertical grinding stones Plate Kusinja hammer mill The Kusinja maize mill is designed to be powered by diesel motors of between 1020 hp, and the milling capacity will vary according to the power source.

Our product range includes a wide range of hammer mill with blower 150 kgs/hr for making fine flour, coffee grinding mill, cassava flour grinding mill, mini grinding mill, maize grinding hammer mill and mini flour grinding mill.

mobile hydraulic cone crusher 128 ton hr High Speed Cone Crusher PS Series Core Crushing Equipments ... Core Crushing Equipments Pvt. Ltd. Offering High Speed Cone Crusher PS Series in Mumbai, Marashtra. ...

grinding machines 30 ton grinding machines 30 ton vertical grinding mill 30 ton hr,, 30 Tons is a commercial machine that gives you all the power you will need to 30 Get Price 04/03/2019 · You can also make fixtures for bending steel of any sort It''s quite a handy grinding machines 30 ton kzntarcozagrinding machines 30 ton .

See this useful summary Table of Bond Work Index by Minerals. For any circuit, whether a crushing circuit, a rod mill, or a closed ball mill circuit, the Work Index always means the equivalent amount of energy to reduce one ton of the ore from a very large size to 100 um.

today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill

ENGSKO Millstones. The most essential part of the mill is the millstone, which is perfect for grinding of healthy, organic wholemeal flour. The quality of the millstone is decisive both for the grinding capacity of the mill and the quality of the ground product.

When working in largescale land clearing, wood processing or greenwaste recycling, you can count on the newly redesigned HG6000 to give you the power and performance you deserve. The HG6000 features a CAT Crated C18 Tier 4 Final engine specifically chosen to meet the demands of your operation as well as those set by governmental regulations.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

vertical mill for ink grinding. Vertical sand mill machine, Grinding Mill for Paint YouTube. Jan 18, 2017 With the use of latest in equipment and quality material, . Get Price And Support Online; mills for grinding grainamerica – Grinding Mill China. Vertical Mill Capacity Rock Phosphate Grinding .

is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller configurations for a single grinding table can be realised. The first Type LM D modular coal grinding mills were developed in 1980 and employed for .

Baileigh has a metal milling machine to fit your needs and budget, whether you''re working in your garage or a large industrial shop. We offer 2 vertical mill lines: economical E models and production mills that last for decades. Why buy a milling machine from Baileigh instead of a competing brand?

Heavy Duty Milling Machines. Kent USA combo horizontal/vertical mills offer both the capabilities of a vertical mill and a horizontal mill in one design. Changing the setup from one operation to the other is quick and simple. This results in significantly reduced setup times.

500 ton per hr crusher price VSI Equipment | KPIJCI and Astec Mobile Screens Our VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour.

MiningLeader is one hightech enterprise, which involves RD, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments.

Falcon has been involved with gravity concentration for the last years, having designed two distinct ranges of equipment; a semicontinuous Falcon SB range for installation into grinding circuits and the recently released Falcon C range for preconcentration and scavenging in a wide range of mineral industries. Understanding the Gold Centrifuge by Comparing it with a Sluice Box Our biggest ...

Mar 09, 2013· 1 ton ball miill operating 24 hrs a day near chinhoyi zimbabwe ... 1 ton per hr ball mill in operation Andy Whyte. ... YUXIANG Machinery 1200/1100 wet pan mill,gold grinding machine,gold mill ...

(#10) to 20,000 #/hr.(#63). VERTICAL MILLS These mills are designed for super fine grinding and producing products in the subsieve range. Two different size models are available (18" and 35") and provide capacities from 100#/hr. to 1,000#/hr., fineness 95 finer than 510 microns. Materials which can be pulverized in the vertical mill ...

325 mesh limestone grinding mill 20 mt hr production Posted: . With a fineness of 325 mesh and an output of 20 tons per hour, this is not possible with small equipment.

Aug 13, 2015· Vertical Mills. A significant portion of the cost to produce a ton of cement resides in the grinding costs. The industry standard for decades has been horizontal ball mills which rely upon heavy balls cascading inside a fast turning mill to crush the clinker into the fine cement powder.

The HIGmill comprises a mill body, shaft with grinding discs, shell mounted counter rings, gearbox, and drive. The grinding chamber is filled up to 70% with grinding beads. Rotating discs stir the charge and grinding takes place between beads by attrition. The number of discs (grinding stages) depends on the application and can be as high as 20.

WhatsApp)

WhatsApp)