RMS Roller Grinder | RMS Roller Grinder

a better grind starts with a better mill. home. rms roller grinder

WhatsApp)

WhatsApp)

a better grind starts with a better mill. home. rms roller grinder

mill installation For some reason it is extremely common to try and align the mill brackets with the two large hexagonal openings on the side of the trolley. The brackets are designed, however, to align with the four tapped holes on the underside of the trolley, not the two hexagonal shaped holes on the side.

Application Fields of Superfine Grinding Mill Superfine Grinding Mill used in the superfine grinding of talc, wollastonite, kaolinite, barite, mica, graphite, vermiculite, pyrophyllite, brucite, silica, aluminum hydroxide and other material, chem...

WoodRiver® Pepper Mill Grinder Kits offer quality and flexibility. Our kits feature tempered stainless steel mechanisms that provide a lifetime of grinding and come in .

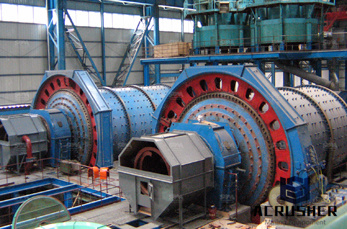

grinding mills are available at a low total cost of ownership due to low installation and operating costs, as well as simple maintenance. We can help you determine the optimum setup for your needs to maximize the profitability of your operation. Support from ''s grinding experts. Every mining operation has a unique grinding process.

Install the Zaxis stepper motor and run the zaxis through the complete range of travel. I like to put a block of wood on the table of the mill just in case something comes loose. Once the zaxis moves smoothly secure the ball screw block and use a pencil to mark the three sides of the ball screw block.

Sep 20, 2018· CHAENG''s 60 years of development is also a history of technological innovation. It is the 60th anniversary of CHAENG this year. Please let''s review the history of technological innovation of ...

system, grinding tables and liners, hydraulic system and drive system. As an OK mill owner, you can benefit from a high degree of spare part flexibility, lower volumes of inventories and consistent maintenance procedures. Cost of installation Reliable largesized mills not .

accompany compact mill installation, add to the excellent economy of the ATOX coal mill. Working principles The raw coal enters the mill via a rotary sluice and feed chute and is discharged onto the rotating grinding table. The rotation of the table accelerates the flow of material towards the grinding track, where the coal is ground

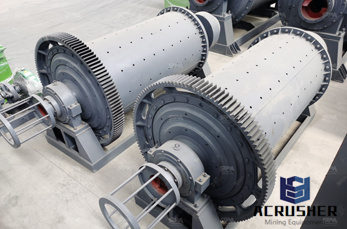

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

Food Confectionery Food Confectionery Confectionery Systems Wet Grinding / Mixing / Homogenizing Dry Grinding Laboratory Tests Toll Grinding Seminars Chocolate Cocoa Press Cake Cocoa Liquor Fillings, Coatings, Chocolate Compounds Special Flours / Protein Shifting Sugar Spices Hydrocolloids Coffee The World of DryGrinding and Classifying ...

The Ultimate In Bead Milling Versatility, Combining The Advantages Of Bead Milling And Circulation Grinding. Circulation Grinding is a costeffective solution for grinding large quantities of material as it allows for a lower cost capital investment in equipment and grinding media than with many other grinding equipment options.

Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair of rollers to increase control response availability and flexibility.

CW Mill''s products include large industrial grinding machines, high performance hammer mill cutting grinding tools, and automotive installation kits for crankshaftdriven after market accessories such as hydraulic pumps, generators, and compressors for special use vehicles.

Regrind mills are difficult to size since work index data are not generally available. Therefore, the design engineer should be generous when sizing a regrinding installation. There is a tendency to employ spent grinding media from the primary grinding installation as media for the regrind mill.

Autogenous grinding should, therefore, be considered and tested when a new plant shall be designed. As a grinding mill is built to last for decades, it is more important to watch the operation costs than the price of the mill installation. The CRRK series of wet grinding pebble mills are tabulated below. Selecting Wet or Dry Grinding Mill

Sep 07, 2018· Mill DRO installation. Glass scale mounting brackets. Digital readout Duration: 13:08. Tinkering Nerd 24,198 views. ... Small Surface Grinder Part 10 S02E35 Duration: 15:38.

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

Stirred Media Detritor (SMD) is a fluidized media grinding mill. It utilizes the rotational energy of the impeller arms to impart a highenergy motion to the media and slurry mixture inside the mill. This results in particletoparticle shear and compressive forces that produce the desired grinding mechanism for fine grinding. Lower capital cost

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

: Victoria Cast Iron Grain Mill. Manual Coffee Grinder, Corn Mill, Seed Grinder with High Hopper. Table Clamp: Kitchen Dining

Installation, Operation and Maintenance of Airflex® Model VC Grinding Mill Clutches Forward this manual to the person responsible for Installation, Operation and Maintenance of the product described herein. Without access to this information, faulty Installation, Operation or Maintenance may result in personal injury or equipment damage.

Jun 04, 2019· This machine is used for gold selecting, also called wet pan mill machine, we have large market in many places, if you are interested in our product, welcome to our factory for a visit, we have ...

Apr 10, 2012· Grinding Mill Installation Preparation Before Installation 1, the grinding mill shall be stored and protected well just before it really is transported for the web site for installation. The surface exposing towards the air shall be coated with all the rustproof grease to be able to resist the weather condition and stop rusting in the.

WhatsApp)

WhatsApp)