(PDF) Planetary Ball Mill Process in Aspect of Milling Energy

The metallization of iron with milling reached % when the time of ball milling was 70 min., while the FeO content decreased with 70 min. of milling from % to %. Read more Article

WhatsApp)

WhatsApp)

The metallization of iron with milling reached % when the time of ball milling was 70 min., while the FeO content decreased with 70 min. of milling from % to %. Read more Article

mill diameter, mill length, grates openings, and pebble ports size; the power equation is also function of all the operational variables selected for this study. The applied force is a function of the mass inside the mill and it is composed of balls, ore and water. The ball charge is a function of the bulk fraction of the SAG mill volume (Jb)

Shear, impact and compression methods are used in media or ball mills. The five types of milling technologies discussed in this article cover more than 90 percent of sizereduction applications in major chemical, food, pharmaceutical, cosmetics and mineral industries. A featured material for each is discussed to bring out the major ...

Rod mills operate at lower speed than ball mills since the rods are rolled and not cascaded. For an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore. The rod charge must be maintained in good working condition, and broken and worn rods must be removed.

Functional performance analysis of ball milling has been described previously by Mclvor. "Coarse" versus "fine" or product particle cutoff size is first selected, usually equal to some benchmark passing size of the circuit product (, 80%). The function of the grinding circuit is to generate new product size material (or "fines") from "coarse" particles in the circuit feed ...

ball mill process in copper production. ball mill process in copper production Competency, Accountability, Transparency Slurry Pumps, Milling Process, Defects, Equipment CustomPartNet Milling is the most common form of machining, a material removal process, which can create a variety of features on, [Chat Online]

milling in a planetary ball mill on its parameters. Kakuk et al. (2009) modelled the milling process in a planetary ball mill and ... the copper powder and the formation of NiCu solid solution coating on the Ni balls. Wang and Wang (2011) studied the microstructure evolution of high energy milled Al50 wt% Si ...

What is a ball mill and how dose it function – The QA wiki. Henan Engineering Technology Co.,Ltd tell you something about Ball Mill: The ball mill is a key equipment to grind the crushed materials, and the ball mill is .

ABC closed circuit, AutogenousBallMillCrusher. Another similar technique is the ABC open circuit where the crusher product feeds the ball mill rather than the autogenous mill. Crusher product is typical feed to a ball mill using large diameter balls but not much grinding of 2025 mm ore can be accomplished in an autogenous mill.

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill. Planetary mills with a single grinding station require a counterweight for balancing purposes. In the Ball Mill PM 100 this counterweight can be adjusted on an inclined guide rail.

main function of copper milling ball mill main function of copper milling ball mill. main function of copper milling ball mill. SUAMG Machinery is professional mineral processing equipment manufacturer in the world, not our equipment has the excellent quality, but also our product service is very thorough.

Main Function Of Copper Milling Ball Mill . Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing A rock tumbler functions on the same principle. Ball The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in Speeding up your Organic Synthesis ...

High circulating load is common in both reverse and direct ball mill grinding circuits. Why? Because the ball mill closed circuit is the last stage before separation. Cyclone overflow should be clean of coarse particles. About the big pump, it''s one of the most important equipment when you are going to .

Production of Aluminum Flake Pigments by Ball Mill ... made of pure copper metal ... wet process of milling using a pilotplant ball mill, as a function of milling time and turns of mill drum as ...

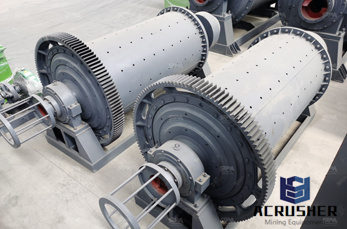

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills

Its ore has a high concentration of copper which significantly complicates gold extractionUltimate product size is 80 % . 08 mm, with up to 60 % 74 µm, at a specific power consumption of 18 to 22 kWh/twet ball milling, as well as reduced circulating load in the mill circuits, due to a finer feed and.

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting .

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

Main Function Of Copper Milling Ball Mill. Our is set scientific research, production and marketing as one of the jointstock mining machinery manufacturing enterprise and now processes three largescale manufacturing base. With the 260,000 square meters of standardized plant and more than 600 devices in different models such as metal ...

discarded due to the high content of copper and hence they are sent to a milling and flotation plant (Slag Mill Plant) for liberation and recovery of copper. This work focuses on optimizing the recovery of copper minerals in copper smelter slags by means of froth flotation. Most of the copper minerals present in the Namibia Custom Smelters ...

» main function of copper milling ball mill » roller flore mills at indore » sintering equipment magnetite sand » mineral oil in phosphate flotation » benefits of vibrating screen; Copper ore a valuable mineral source for all countries.

The Process Of Milling Copper. Copper ore grinding processopper ore grinding mill in india,low costs high availability, sbm ball mill is an efficient tool for grinding walnutsized copper ore into powder there are two ways of grinding the dry process and the wet processontact supplier.

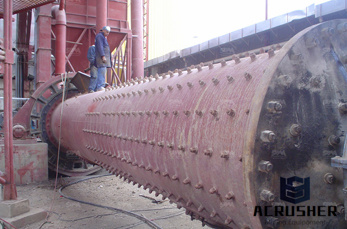

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

main function of copper milling ball. selection function rod milling selection of rod oct this discussion will be limited to testing for selection of rod and ball and ball milling using grinding media of known quality are well nbsp exerciseselection of rod mills in particularboth feed and product streams were sampled for the rod and ball . Bond ...

WhatsApp)

WhatsApp)