Introduction to Grinding Machine YouTube

Nov 21, 2013· The powder making equipment includes raymond mill, high strength mill, high pressure micropowder mill, bucket elevator, electromagnetic feeder, etc. It is used for nonflammable, nonexplosive ...

WhatsApp)

WhatsApp)

Nov 21, 2013· The powder making equipment includes raymond mill, high strength mill, high pressure micropowder mill, bucket elevator, electromagnetic feeder, etc. It is used for nonflammable, nonexplosive ...

Grinding. Introduction . Grinding is a metal cutting operation performed by means of a rotating abrasive wheel that acts as a is generally used to finish work pieces which must show a high surface quality, accuracy of shape and dimensions.

Introduction to Grinding Mills EzineArticles. Mar 22, 2012· Introduction to Grinding Mills A grinding mill is a type of machine sued to break solid materials into tiny pieces. Various types of grinding mills are out there, which are used to grind different types of materials. In the past, mills were run by hand, animals, water and wind.

Mar 22, 2012· A grinding mill is a type of machine sued to break solid materials into tiny pieces. Various types of grinding mills are out there, which are used to grind different types of materials. In the past, mills were run by hand, animals, water and wind. Nowadays, they are powered by electricity as well. Below are different types of grinding mills.

An introduction to grinding grain for flour B aking bread when I was growing up meant first slipping down to the basement larder and grinding the grain. The machine was absolutely deafening, but I loved the smell of freshly milled flour and the way it floated down .

Introduction to Production Steps of Aquatic Feeds (Mixing) • Mixing: The process is as important as grinding. If you grind ingredients but then you should mix them homogenously. So mixing is; • To assist in obtaining a more homogenous grind, • To increase the efficiency of the grinding process: high oil content

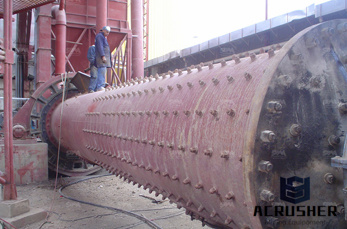

introduction of ball miller machine – CGM Grinding Plant. Ball mill – Wikipedia, the free encyclopedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for .

Ball mill,Ball mills,Grinding mills,Ball mill machine,Ball grinding mill Introduction. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and... Get Price. Grinding in Ball Mills: Modeling and Process Control Cybernetics commonly used control strategies are analyzed and discussed.

Jun 29, 2019· an Introduction to Grinding Mill Plant. Contact Info: amidsheikhi88 +.

Introduction Grinding is the last stage in the process of comminution; in this stage the particles are reduced in size by a combination of impact and abrasion, either dry or in suspension in water. Learn more about Chapter 7: Grinding Mills on GlobalSpec.

Introduction . Grinding – Rod Mills (Large cylinders similar to cement mixer). learn more ; VMA Introduction to the milling technology with the bead mill . The actual dispersion system in a bead mill consists of a milling chamber and an agitator the milling chamber is filled with the grinding beads (material .

Energy Saving Ball Mill Introduction. Ball mill is the key equipment for grinding of crushed materials. It is mainly used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal ore beneficiation, glass ceramic, etc.

Work on a milling machine is most often held in a vise clamped onto the bed. To make features aligned with the edges of the stock, it''s neccessary to align the vise with the feed axes of the mill. To do this, mount the vise on the bed and secure it with Tbolts, but only lightly so as to permit adjustment of the orientation of the vise.

Milling technology advanced further with the introduction of rotary mills. The mola asinaria which dates back 200300 BC was a basic rotary mill driven by blindfolded horses, donkeys or mules and used mainly to grind flour and corn. Sometimes it used human power and was driven by slaves. It had a horizontal axle attached to a shaft which was attached to a runner stone (the .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Jan 25, 2011· Evans'' mills were water powered, so they were situated along rivers. This invention dramatically increased flour production, but produced only one grade of wholemeal flour. Meanwhile, in Hungary, stone grinding was not adequate to grind the hard wheat varieties that grew well there.

introduction to grinding mills peralatan pertambangan; Peralatan Pertambangan Grinding Dan Sirkuit Flotasil. Mesin Flotasi Pertambangan Tambang Logam Klik Untuk . Peralatan pertambangan grinding dan sirkuit flotasi grinding machine is broken again after material crushing the key equipment mangan bijih pemis magnetik, mangan.

introduction of ball miller machine – CGM Grinding Plant. Ball mill – Wikipedia, the free encyclopedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for .

The actual dispersion system in a bead mill consists of a milling chamber and an agitator; the milling chamber is filled with the grinding beads (material glass, zircon oxide, steel) and the product to be dispersed. In the milling vessel, the grinding medium is kept moving by the agitator, which itself is driven by a motor.

Introduction to rod milling using sand. milling grinding rod . rod mill introduction. rod mills are very similar to ball mills, except they use long rods for grinding media. overflow and can be used in first class open circuit grinding and widely used in the first stage grinding in artificial sand and stone, live chat; rods mill for grinding all purpose rod milling range. moly cop ...

Grinding Mill Introduction. Grinding 3 Circuits is a course for process engineers, mill operators and mineral processing studentshis course is the third of a suite of three courses on grinding engineering from Performance Solutions the companion titles are Grinding 1 Fundamentals and Grinding .

In his book, Evans describes a system that allows the sequential milling of these grists, noting that "a mill, thus constructed, might grind grists in the day time, and [do] merchantwork at night." Over time, any small, older style flour mill became generally known as a gristmill (as a distinction from large factory flour mills).

WhatsApp)

WhatsApp)