Areal discharge top coal caving 4 YouTube

May 11, 2019· Discrete element modeling of longwall top coal caving areal discharge from 4 discharge holes. ... World''s Dangerous Idiots Construction Excavator Heavy Equipment Operator Driving Machines ...

WhatsApp)

WhatsApp)

May 11, 2019· Discrete element modeling of longwall top coal caving areal discharge from 4 discharge holes. ... World''s Dangerous Idiots Construction Excavator Heavy Equipment Operator Driving Machines ...

Dec 04, 2018· Longwall TopCoal Caving: A Productive and Efficient Alternative . December 4, 2018 In the right conditions, longwall mining is one of the safest, most productive and most efficient ways to produce coal. This is owed in part to the high degree of automation employed by modern longwall operations, which keeps shearers and roof supports advancing smoothly and people far from the .

Apr 30, 2015· The Principle of Longwall Top Coal Caving (LTCC) Chinese ... Top 10 Fascinating Attempts at ... World''s Dangerous Idiots Construction Excavator Heavy Equipment Operator Driving ...

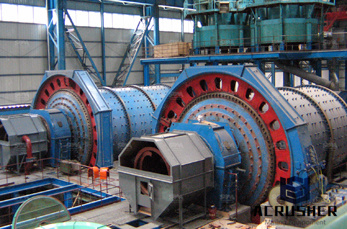

equipment for a Longwall Top Coal Caving face. Photo courtesy of Joy Manufacturing Company Pty Ltd. A brief description of longwall top coal caving (LTCC) is included at the end of the Longwall section of the Fundamentals of Coal Mining module of this web site. Despite the fact that there are numerous coal seams in Australia which are thick ...

topcoal caving operation with a large mining height ... The study has developed the key technologies for improving the reliability of equipment at the coal face and has overcome the challenges in equipping the topcoal caving face with a large mining height in ultrathick coal seams; 3.

Longwall Top Coal Caving. The longwall top coal caving (LTCC) mining method to be employed at the Eynez East underground coal mine is a special type of longwall mining applicable to seams thicker than 6 meters (20 feet). Conventional longwall equipment has not yet been designed to operate successfully in seams thicker than approximately 6 ...

Jul 19, 2018· Equipment Selection of Longwall Top Coal Caving Mining. The space behind the rear legs of the powered supports is large enough to allow lateral and .

Longwall Top Coal Caving. Longwall top coal caving (LTCC) is a special type of longwall mining applicable to very thick seams (greater than ) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to .

Top Coal Caving Equipment. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Jul 02, 2014· Longwall Top Coal Caving. The longwall top coal caving (LTCC) mining method to be employed at the Eynez East underground coal mine is a special type .

top coal caving equipment. Home / top coal caving equipment; 102 Things To Do in Greater Morgantown. 102 THINGS TO DO IN GREATER MORGANTOWN! This list will get you started enjoying some of what Greater Morgantown has to offer. Be sure to download or print ...

Longwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically – m (2 ft 0 in–3 ft 3 in) thick). The longwall panel (the block of coal that is being mined) is typically 3–4 km (– mi) long and 250–400 m (820–1,310 ft) wide.

Not all the coal would be recovered, but recoveries of 7580% of the full seam in the block are achievable. The system also allows the initial mining height to be reduced to a preferred working height without losing coal. The Top Coal Caving is a Modified Longwall Mining system. Equipment Selection of Longwall Top Coal Caving Mining

PDF | A good understanding of the caving mechanisms of loose topcoal is significant for longwall topcoal caving (LTCC) mining. In this paper, the equations of the particle motion, topcoal ...

How does top coal caving work? Case study – Austar Acknowledge the assistance of: Austar website Ellton Longwall website China National Coal Mining equipment website: /;˝ ˛ ˜,, China Overseas Development co website Kurt Ekanayake – Austar commissioning and now Principle Mining Engineer AMC ˛ 1 3 < 2˛3˛

Sep 10, 2008· The longwall was a China National Coal Mining Equipment (CME) top caving face, 240 metres wide and with a 2km panel length. The operation is a 365 days, 24/7 operation. The mine, which features two top coal caving faces and which has been operating since January 2005, has planned utilisation to keep the output conveyor belt full.

The Principle of Longwall Top Coal Caving (LTCC) YouTube. Jul 2, 2019 The Principle of Longwall Top Coal Caving (LTCC) YouTube . Visit. The Principle of Longwall Top Coal Caving (LTCC) ... Miner working in a confined, cramped position inside a narrow coal seam on a piece of equipment called a ''lizard. Kay Urwin.

The topcoal caving mining recovery rate is one of the important indexes of evaluating mining technical measures. This paper, by using the similar model and numerical simulation on the ...

Longwall Top Coal Caving (LTCC) is a special designed longwall mining method for very thick seams (thickness is more than ) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond around 5m mining height.

assigned a uniform height of and the top coal was assigned with remaining height of the coal seam. The bottom part was extracted using the normal longwall extraction method. The top coal was extracted in such a way that it mimics the real top coal caving mechanism, top coals located

Yancoal introduced the Longwall Top Coal Caving (LTCC) mining technology to Australia at its Austar mine in 2006. Developed in China, top coal caving uses a modified long wall mining system. LTCC allows the excavation of thick coal seam...

AbstractLongwall top coal caving (LTCC) techniques has been employed in favourable geological conditions widely in China since the mid80s and in Australia recently. With the improvement of highlypowered face equipment and the method itself, in the past 15 years, LTCC was introduced to more challenging geological

53 Mining Safety of Longwall Topcoal Caving in China Jian Wu, 1 Yueping Qin, 1 and Minghua Zhai1 1China Univ. of Mining and Technology, 011# Xueyuan Road, Haidian Dist, Beijing 100083, of China; 2Zhangji Coal Mine, Xuzhou Mining Bureau, Xuzhou 221147, Jiangsu Province, of China ABSTRACT Longwall topcoal caving technology has developed rapidly in China, in recent years.

The topcoal caving mining method, developed steadily in the past two decades, has become the main method for thick seam coal mining in China. In recent years, the core research areas in the topcoal caving mining are the mechanisms of topcoal caving and the improvement of topcoal recovery ratio.

WhatsApp)

WhatsApp)