What is the mining method used to mine iron ore Answers

Sep 14, 2011· The mining method used to mine iron ore depends on the placement of the ore body and surrounding environment. Addition below I would say the majority (over 95%) or iron ore .

WhatsApp)

WhatsApp)

Sep 14, 2011· The mining method used to mine iron ore depends on the placement of the ore body and surrounding environment. Addition below I would say the majority (over 95%) or iron ore .

Iron mining in the United States produced million metric tons of iron ore in 2015, worth US billion. Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and of the iron ore was mined in northern Minnesota''s Mesabi Range.

Iron ore is unrefined iron. A player with a Mining level of 15 or higher can mine iron ore from iron rocks found in various mines, granting 35 Mining experience for each ore mined. It takes seconds (9 game ticks) for each ore to respawn within an iron rock. Lower level players often train...

from raw iron ore samples by passing them through a number of furnaces with progressively higher temperatures. The LOI is a measure of the water content of the ore and an important step in iron ore analysis. When ore is fed into a blast furnace, the water contained in it .

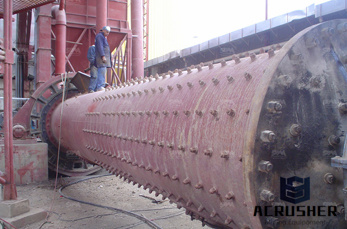

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Iron Ore (15 60) Surprisingly, power mining (not banking ore) Iron ore is the fastest method to get your mining level up in the game. Taking advantage of three rock mining spots is key to power mining. These are located in Alkharid, Legends Guild, Piscatoris, Verdant Valley and Mount Karuulm.

Iron ore was won by drilling and blasting ().As mining technology generally developed, so did drilling techniques and the explosives used. Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as "dogger") allowing mine drivages to be selfsupporting. However, he states that in later years where the mining had progressed to the dip, this ...

Underground mining is practical when: The ore body is too deep to mine profitably by open pit. The grades or quality of the orebody are high enough to cover costs. Underground mining has a lower ground footprint than open pit mining. The underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised ...

These percentages may be arbitrary or may be based upon experience with deposits of the particular type in question and with the mining method to be used. Thus, in one district experience has shown that a 10percent deduction should be made for loss of ore in mining .

Impervious shales form the bottom of the ore bodies. Many of these ore bodies do not extend to the surface and thus the ironformations are sufficiently deformed so that it was necessary to utilize underground mining methods rather than the large openpit .

Methods Of Mining Iron Ore. due to being the safest layers to mine where all ores exist in reasonable quantities especially diamond, layer 10 to 15 are usually considered the best area in which to start mininghe single best layer for mining is highly debated and is not agreed on using the debug screen f3 is the easiest way to find the players altitude the player can also look for ...

As mining techniques and the price of minerals improve, it is not unusual for tailings to be reprocessed using new methods, or more thoroughly with old methods, to recover additional minerals. Extensive tailings dumps of Kalgoorlie / Boulder in Western Australia were reprocessed profitably in the 1990s by KalTails Mining.

Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted. Iron ore mining is classified into two categories manual mining and mechanized mining methods. Haematite and magnetite are the most commonly found iron ore minerals. Deposits of iron ore such as haematite containing iron oxide are found in sedimentary rocks from which the oxygen is removed from the ...

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive

A Underground Method of Mining Iron Ore. Previous Next ... The first mining methods were very crude. In the experience of ten years they have been rapidly advanced, until now they are fully abreast of the best modern mining practice. In all this upward movement in mining methods it is evident that necessity in a great degree compelled progress.

Iron ore is an ore always in demand, due to its use in producing iron and steel bars via Smithing. There are many locations to mine iron ore, but one of the best members'' places to mine iron for banking is Ardougne Monastery. It has six iron rocks total that are all very close to each other...

Iron ore is an item always in demand, due to its use in Smithing iron and steel bars. There are many locations to mine iron ore, but one of the best methods is mining in the Dwarven Mines. Near the Dwarven Mine resource dungeon are three iron rocks very close together as well as a bank deposit...

Introduction to Iron Ore and Steel Smelting Processing. Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter. Here the ore is put into a blast furnace along with limestone and coke and subjected to hot ...

Mining Methods. Truck Shovel / Loader; Summary: Operations consist of an open pit truck and shovel mine, a concentrator that utilizes single stage crushing, AG mills, magnetite separation and floatation to produce hematite and magnetic concentrates that are then supplied to the onsite pellet plant. ... 8 M long tons of iron ore pellets: 8 M ...

These are surface mining and underground mining (sub surface mining). Iron ore is almost exclusively mined by surface operations. The most predominant surface mining methods used for mining of iron ores are open pit mining methods and open cut mining methods. However a few underground iron ore mines are also in operation around the globe.

Sep 04, 2018· Level 1599: Powermining Iron Ore. Many of OSRS best players will use this method to train their mining. While players can access iron ore at level 15 mining, a thorough understanding of Runescape mechanics is needed to maximize efficiency using this method. Experience per hour ranges from 40k65k experience per hour.

describe the characteristics of the ore deposits that governed the selection and application of the mining methods employed in each case, describe the methods and practices employed, and present the costs of mining under the described conditions by the methods used, thus giving a complete picture.

Underground mining of natural iron ore deposits occurred on the Mesabi Range in northeastern Minnesota from 1892 to 1961. The Mesabi Range is the ledge rock exposure of the Biwabik Iron Formation, a geological feature that stretches in length for just over 100 miles, from west of Grand Rapids in Itasca County to east of Babbitt near the St. Louis / Lake County line.

Apr 09, 2015· Exploitation of existing iron ore deposit is the easier part of the mining operations. The harder part is to find new ore deposits and to define their extent and the iron content (grade). Exploration is the process by which the accumulations of iron ore minerals can be found in the earth''s crust.

WhatsApp)

WhatsApp)