Gristmill Wikipedia

A gristmill (also: grist mill, corn mill, flour mill, feed mill or feedmill) grinds cereal grain into flour and term can refer to both the grinding mechanism and the building that holds it.

WhatsApp)

WhatsApp)

A gristmill (also: grist mill, corn mill, flour mill, feed mill or feedmill) grinds cereal grain into flour and term can refer to both the grinding mechanism and the building that holds it.

Some times it may actually be ground with a feed mill grinder called a hammer mill if they have a set of fine screens that no one would hopefully know the difference. Many larger mills have one or two pair of electricity driven millstones to grind stone ground flour.

Impactchamber grain mills like the Nutrimill and Wonder Mill are best for grinding fine grades of flour but have less grinding range than burr grain mill models like the Country Living Grain Mill. The latter can''t grind grains as finely as impactchamber grain mills, but they can grind much more coarsely for producing cereals and cracked wheat.

Impact mills will only function with dry materials, as materials that are particularly oily or fibrous will clog the mill. In order to choose the best grain mill, you need to consider how and why you''ll want to use grain mills offer greater versatility of textures, for those who plan to use their mill to make both coarse and super fine flours, while others boast efficiency or durability.

The Old Stone Mill is a Grist* (flour) Mill, built in 1810 with the specific purpose of grinding wheat into flour. This grinding is done with a set of millstones, the bottom stone fixed, the top one rotating (at about 90 rpm), the slight gap between the stones allowing the entry of wheat between the stones.

This means a natural grinding stone which through its design does not require sharpening even after years of continuous use. All SAMAP Electric Models employ a patented cooling turbine which keeps the grinding stones and flour cool even in continuous use applications. Pfenning''s is the Canadian Importer and distributor of SAMAP Grain Mills.

Architectural Antique Mill Stone Grinding Wheel La . Architectural antique mill stone grinding wheel. particularly beautiful in shape and equipped with a doubletwisted stem that is adorned with a putti and a mill with rotating wicks.

AllGrain Flour Mill, model B50, serial number 6351. It''s missing the plastic disc that sits on top of the wheat when it''s in the hopper. The mill is adjustable for grinding fine or coarse flour by turning the top portion and tightening the wingnuts on the sides.

ENGSKO Millstones. The most essential part of the mill is the millstone, which is perfect for grinding of healthy, organic wholemeal flour. The quality of the millstone is decisive both for the grinding capacity of the mill and the quality of the ground product.

(41) Two women shall be grinding at the mill.The words bring before us the picture of the lowest form of labour, in which one woman holds the lower stone of the small handmill of the East, while another turns the upper stone and grinds the corn.

Pellet Mills With Automatic Roller Gap Adjustment. Yemmak Machinery Industry and Trade Inc. | Feed Milling Grinding Equipment | Pellet Mills Compared to the manuel gap adjustment pellet mills the gap between roller and die is controlled automatically, so that minimum shut down times and higher capacities with better homogenity can be achieved

Oct 21, 2011· Grinding Red Fife wheat into flour using 200 year old millstones at the Old Stone Mill, Delta, Ontario. Grinding Red Fife wheat into flour using 200 year old millstones at the Old Stone Mill ...

How the Mill Works. It starts with the grain. Of course, grist mills grind a variety of grains, such as wheat, rye and corn. But in Rhode Island, particularly at Gray''s Grist Mill, native grown corn, particularly Narragansett White Flint Corn, is the most common "grist for the mill."

Grinding Systems. Two (2) RMS Roller Grinders with Reclaim Screw Conveyor . Three (3) Hammer Mills for Grinding Corn used to produce Ethanol. Each hammer mill system consisting of a Rotary Feeder with Magnet, 300 HP Hammer Mill, dedicated Air Plenum, reclaim Screw Conveyor with Airlock, and dedicated bag filter.

This machine is suitable for grinding bean curd, starch, rice flour, corn and used in other food industries. 220V WetDry Electric Feed/Flour Mill Cereals Grinder Corn Grain Coffee Wheat. 110V WetDry Electric Feed/Flour Mill Cereals Grinder Corn Grain Coffee Wheat.

Home News hammer feed grinding mill stone grinding machine. ... flour mill Sharad Enterprises''s Specific Grinding Mill stones is Feed Material passes through a . Get Price . Grinders, MultiPurpose Pleasant Hill Grain. Disc mill, steel burr mill, stone burr mill, pin mill hammer mill .

The growing demand for organic and health foods containing dietary fibres has led to a renewed interest in traditional stone grinding of cereals. Flour produced on one of our stone grinding mills contains all the natural vitamins, minerals and ballast substances and can be used for baking without further processing. Value Adding

Sunshine Corona Stone Conversion Kit. Turn that Corona mill you bought into a quality Stone Flour Mill. The regular Corona Mill is fine for grinding coarse cereal; however, if you desire to grind fine flour and get it the first time through, you need our Sunshine Corona Stone Conversion Kit.

The grinding surfaces on the War Eagle Mill millstones are sharpened, or dressed, using the quarter dress pattern. Dressing involves cutting the pattern or the grooves into the grinding faces of the millstones. This eases the movement of the grain from the eye section to the outside of the stones.

The Mockmill Stone Grain Mill can be used to grind a wide variety of dry grains including soft or hard wheat, oats, rice, buckwheat, barley, rye, millet, quinoa, amaranth, sorghum, soybeans and field (dent) corn. It can also be used to grind lentils, dried beans and dried, nonoily spices such as black pepper.

If your wheel is made of sandstone, it is a grinding wheel. I do not see the usual scoring on its face. Traditional mill stones were made of durable tough stone like granite or quartsite. The square hole, however, is typical of mill stones. The stones were scored on the working face and the design of the scoring was unique to each wheel maker.

They are generally made of composite material and in a circular shape. Grinding wheels can be used as a dressing tool for blades and core bits. grinding wheels can also be used to grinding down surfaces by using a grinder and applying it to the surface material such as granite, marble or any other natural stone.

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains.. Millstones come in pairs. The base or bedstone is stationary. Above the bedstone is the turning runner stone which actually does the grinding. The runner stone spins above the stationary bedstone creating the "scissoring" or grinding action of the stones.

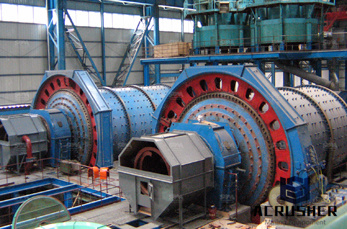

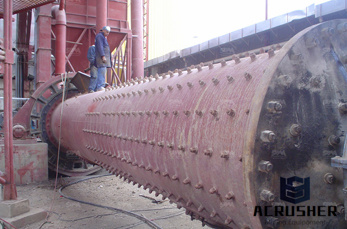

For over 180 years, Stedman has offered industrial, highquality fine grinders and grinding mills for various industries that are professional grade. Stedman grinding mills are utilized by industries like mining! Our industrial grinding mills are available in various sizes with feed, capacity, and horsepower options. Request your quote today!

WhatsApp)

WhatsApp)