Vancouver Island pulp mill supplies materials for medical ...

Apr 04, 2020· A pulp mill on Vancouver Island that supplies American producers with materials to make surgical masks and other medical supplies has been dragged into a .

WhatsApp)

WhatsApp)

Apr 04, 2020· A pulp mill on Vancouver Island that supplies American producers with materials to make surgical masks and other medical supplies has been dragged into a .

Aug 21, 2020· Today, steel production makes use of recycled materials as well as traditional raw materials, such as iron ore, coal, and limestone. Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for virtually all steel production.

The task of a feed mill consists of blending a set of raw materials and additive premixes in order to produce a feed according to a specific formula. Then, to ensure the compliance of this manufactured feed with legislation and the product label, the finished product and the raw materials that compose it must be submitted to a quality control plan.

The largest mill, situated in Metro Manila, has an annual output of 250 000 t, and the five largest account for 40 percent of the total production nationwide. The feed industry''s share of the total market for feeds in 1980 was 2 million t, representing approximately 60 percent of total feed consumption for that year.

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

The raw materials purchased are not necessarily the same as the raw materials that will be used in production. This is because there might be changes in raw material inventory. It would, for example be possible to use raw materials in a period without having to purchase any if there were already enough raw materials in inventory.

Raw materials are extracted from the quarry, then crushed and ground as necessary to provide a fine material for blending. Most of the material is usually ground finer than 90 microns the fineness is often expressed in terms of the percentage retained on a 90 micron sieve.

only some species are useful for biofuel production. Although the properties of oils and fats used as raw materials may differ, the properties of biodiesel must be the same, complying with the requirements set by international standards. Typical Oil Crops Useful for Biodiesel Production

Jan 01, 2012· Direct material cost = Opening stock of raw materials + purchase of raw materials + carriage inwards – returns outwards – closing stock of raw materials. ... · The purchase of finished goods is added with cost of production in the trading account. ... The teaching procedure is set in such a way that the learner gets a real feel of the work ...

materials with iron ore exports growing from about 150 Mt to 800 Mt. Coal and coke Coking coal is a key raw material in steel production. As iron occurs only as iron oxides in the earth''s crust, the ores must be converted, or ''reduced'', using carbon. The primary source of this carbon is coking coal.

Nov 07, 2019· Raw materials are materials or substances used in the primary production or manufacturing of goods. Raw materials are commodities that are bought and sold on commodities exchanges worldwide.

Raw Materials Probably half of the fiber used for paper today comes from wood that has been purposely harvested. The remaining material comes from wood fiber from sawmills, recycled newspaper, some vegetable matter, and recycled cloth. Coniferous trees, such as spruce and fir, used to be preferred for papermaking because the cellulose fibers in ...

The shooting flame that can easily be seen from I77 comes from a stack atop the No. 1 Steel Producing building. The flare is a pollutioncontrol device, burning off gases from the steelmaking ...

Jun 12, 2013· Raw materials (ingredients, processing aids, and packaging materials) are the foundation of finished food products. As such, they must meet regulatory requirements (safe and legal for your intended use) and your specifications (contribute to .

Cement Gypsum Clinker Limestone Ingredients Grinding Mill. In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60% ...

Manufacturers pay for labor and overhead to work on those raw materials. After they go into production, raw materials become workinprocess inventory. When completed, workinprocess inventory becomes finished goods. Just as with a retailer, .

Marlin Steel Wire Products . 2648 Merchant Drive Baltimore, MD . Phone (410) Fax (410)

In 2014, the United States was the world''s thirdlargest producer of raw steel (after China and Japan), and the sixthlargest producer of pig industry produced 29 million metric tons of pig iron and 88 million tons of steel. Most iron and steel in the United States is now made from iron and steel scrap, rather than iron ore.

RAW MATERIALS. Efficient use of natural resources is critical to sustainability. The steel industry uses advanced technologies and techniques to increase production yield rates, reduce its energy requirements, and facilitate the use of byproducts. On average, 20 GJ of energy is consumed per tonne of crude steel produced globally.

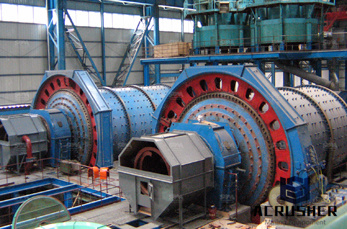

Hammermill, a mill using little hammers to crush the material IsaMill, an energyefficient mineral industry grinding mill that was jointly developed in the 1990s by Mount Isa Mines Jet mill, grinds materials by using a high speed jet of compressed air or inert gas to impact particles into each other.

I have been facing this problem lately: The biggest part of my industrial area requests raw materials! Before suggesting something please be aware of the following facts: *It''s not a traffic issue. I have 2 raised highways leading straight to the industrial area and congestions are a problem only in the residential area of my + population city.

Apr 19, 2007· You should not rely on receiving data since raw materials may be used out of rotation. The most common way to document raw material use is on the production records. These can be a batch sheet, production formula sheet, etc. Regardless of how it is documented, a system for tracking when you use a specific lot and the quantity used is essential.

Modeling Based On The Extreme Learning Machine For Raw, Mar 21 2015 abstract vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production raw material grinding process in cement industries accounts for approximately 5060 of the total energy consumption Grinding Mill Cement Plant In Chinese

1) Calculate and share detailed raw material demand forecasts at regular intervals with service centers and mills . By sharing what we call a "material demand profile" with the sources of the raw material, OEMs can reduce risk for their raw material suppliers enabling them to operate more responsively, while increasing the OEMs ability to control pricing and ensure availability.

WhatsApp)

WhatsApp)