Optimum choice of the makeup ball sizes for maximum ...

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball mills Article (PDF Available) in Powder Technology 246:625–634 · September 2013 with 490 Reads How we .

WhatsApp)

WhatsApp)

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball mills Article (PDF Available) in Powder Technology 246:625–634 · September 2013 with 490 Reads How we .

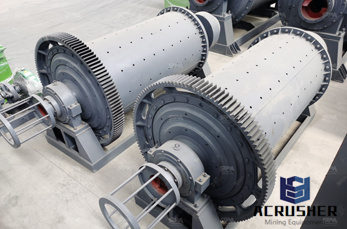

The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition.

Optimum Ball Size In Ball Mill. ... Ball mill machines for precious metals stone crusher machine precious stone crushers in south india mine stamp mill for sale in south africa crusher machine dark grey and could contain haardous concentrations of trace precious metals the stone was.

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

The lower impact forces are due to a combination of both smaller ball masses and lower drop heights resulting from the use of smaller balls and smaller mill diameters, respectively. The feed ore in primary grinding mills is typically very abrasive owing to its particle size, shape, and mineralogy.

Opening the ball mill box reveals a user''s manual, a mill base, two mill jars, and five extra drive belts. Unpacking the Ball Mill The ball mill jars The first thing that struck me when I first looked at these mills was the nice quality of the mill jars. These things are really heavyduty, and have a very solid closing and sealinglid assembly.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

Calculate and Select Ball Mill Ball Size for Optimum Grinding ... Feb 17, 2016 ... In Grinding, selecting (calculate) the correct or optimum ball size that allows for the ... Well, this safety factor can cost you much in recovery and/or mill liner wear and tear. ... In his paper "The Preferred Size of Balls for Ball Mills. Read More

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Nov 13, 2012· In this video I feature the ball I just made with misc material I had laying around the house and shed. During the time it took to edit and post this video I ran the charcoal through the mill and ...

How should we select ball (size, grading) for preparation of Ceramic material by Planetary mill? ... Size of the milling balls should not be more than 34 orders of magnitude larger than your ...

running in such a way as to be close to the optimum pulp density (73% in the above example). It must be kept in mind that the optimum is always very close to the unstable zone. Influence of balls filling degree The performance of ball mills is very sensitive to the ®

Table of ContentsOptimum Size of BallsTests with Different Mixtures of Balls in Conical, Cylindrical, and Grid MillsClosedCircuit Grinding Several years ago, Davis assumed that the rate of wear of the different sizes of balls in a ball mill was directly proportional to the weight of each ball, and he evolved a formula for calculating a balanced charge. Operators have used this formula when ...

and with the decreased grain size, the necessary ball size also decreases (Olejnik, 2010; 2011). For each grain size there is an optimal ball size (Trumic et. al., 2007). The bigger ball in relation to the optimal one will have an excess energy, and consequently, the smaller ball mill has less energy necessary for grinding. In both

Optimum Ball Mill Speed; ... This liner is made of the best grade white iron and is most serviceable for the smaller size mills where large balls are not used. Hard iron liners have a much lower first cost. Electric steel, although more expensive than hard iron, has advantage of minimum breakage and allows final wear to thinner section. ...

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill – The general operation of a grinding mill is to have the product impacted between the balls as ...

A ball diameter that grabs the particle must exceed the particle by 25 times to achieve this semiself locking taper. One can argue the f50 is a more realistic value since balls wear and the average ball size might be closer to half the maximum. Then the multiple would be closer to 13 times the maximum particle size fed to the ball mill.

How to decrease particle size of alumina powder with ball milling? ... Normally the amount of balls should be 5055% of the apparent volume of the mill, as in a normal ballspacking we have about ...

Oct 19, 2017· Bond formula for the grinding balls size calculation October 19, 2017 · Archive · 0 . The enterprises consumers grinding media have a question about right choise the grinding ball size (diameter) for the mill in order to achieve the required grinding quality.

The model for optimal charge in the ball mill J. Min. Met. 43 A (2007) 23 For each narrow size distribution of quartz there exists a ball diameter which gives the highest grinding rate, and that ...

How can one select ball size in ball milling and how much material should be taken in mill pot? ... I need info about the ball mill size to the balls had opted for steel ball due to cost ...

Best way to determine the balltopowder ratio in ballmilling? ... If you want to reduce the particle size, you should use small balls with slow rpm to get cascading effect and if you want to mix ...

Request PDF on ResearchGate | On May 1, 2014, Bwalya and others published Exploring ball size distribution in coal grinding mills

The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ranges from 1 to 0 as particle size equation produces a maximum in S, and the particle size of the maximum is related to ball diameter by x m = k 1 d variation of a with ball diameter was found to be of the form ...

WhatsApp)

WhatsApp)