Nemaska Lithium Ore beneficiation YouTube

Jun 09, 2017· Discover the ecofriendly and innovative aspect of the ore processing methods developed by Nemaska Lithium with Caroline BoudriasChapleau, Process Engineer Mineral Processing.

WhatsApp)

WhatsApp)

Jun 09, 2017· Discover the ecofriendly and innovative aspect of the ore processing methods developed by Nemaska Lithium with Caroline BoudriasChapleau, Process Engineer Mineral Processing.

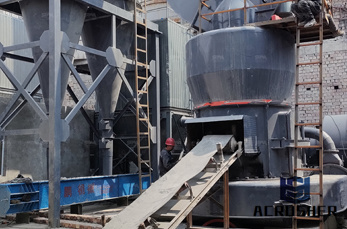

Lithium Ore Processing Equipment Fote Machinery(FTM) Lithium ore whose proportion is low is a relatively special metal ore. Lithium ore is widely used in many fields such as architecture, chemical engineering, spaceflight and so on. With its research expansion, it applies in military industry as a kind of high quality metal.

seml2ciron ore processing plant Lithium ore processing plant. Zenith Machinery offers complete set of lithium ore beneficiation equipment, which consists of crushing, screening, grinding, ... seml2ciron ore processing plant Lithium ore processing plant.

Lithium ore processing methods, there are handselection method, flotation method, chemical or chemicalflotation combined method, thermal cracking method, radioactive selection method, particle flotation method, the first three methods are commonly used. This lithium ore processing plant mainly use flotation, highintensity magnetic separation methods.

Lithium ore, lithium and it is substance after the assumption, the 2nd world war the great importance of military and civilian. For many is regarded as lithium compounds are already skyrocket propellant and utilised in nuclear reactors. Lithium minerals are mainly utilized in the manufacturing of lithium .

our products. Heavy Industry has always delivered the right equipment at the right p. Financial Servs offer a variety of tailored financing solutions and worldwide shipping arrangements for .

Spodumene theoretically contains % Li2O and therefore the production of this mineral is greatly increasing because of the expanded use of lithium in the manufacture of high temperature insoluble lubricants, ceramics, pyrotechnics, nonferrous welding fluxes, air purifying agents, and hydrogen isotopes. Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on .

lithium ore processing plant Newest Crusher, Grinding Mill, Lithium Wikipedia, the free encyclopedia Lithium (from Greek lithos ''stone'') is a chemical element with symbol Li and atomic number 3 It is a soft, silver, Platinum Ore Crusher Processing,Platinum Ore Beneficiation Processing .

An alternative concept for lithium minerals processing has been published by ANZAPLAN and described in Minerals Engineering Journal. It exploits the characteristics of typical pegmatite host rocks the coarse primary crystal size and the differences in color and morphology of the minerals within the ore.

Processing of lithium ore, like most minerals, begins with beneficiation prior to extraction of its compounds in downstream processes. The aim of this review is to consolidate current literature on beneficiation of lithium from lithium bearing economic ores. Physical separation techniques such as heavy media and magnetic separation, flotation ...

Jan 11, 2017· Lithium is a chemical element with the symbol Li and atomic number 3. It is a soft, silverwhite metal belonging to the alkali metal group of chemical elements. Lithium prices exploded by 60 ...

Jan 15, 2019· The Greenbushes Lithium Operations has two processing plants; one producing technicalgrade lithium concentrate and the other producing chemicalgrade lithium concentrate. The ore is upgraded using gravity, heavy media, flotation and magnetic separation to produce these lithium concentrates according to the flowsheet shown in Fig. 8.

Lithium Ore To Lithium Iron Processing Pkant Lithium News, Market Prices Lithium Today. Increasing lithium royalties contributions The Western Australia''s resources royalty revenue is down 164 million thanks to iron ore losses – but that has been partly offset by increases in gold and the new darling of the mining industry, lithium. ...

Mar 14, 2013· WESTERN LITHIUM USA CORP. LITHIUM EXTRACTION / PROCESSING. Western Lithium USA Corporation is developing its Nevada lithium deposit to support the new generation of hybrid/electric .

viareggio(lu) via leonida repaci 16 / b cap 55049

Jul 14, 2016· Lithium Extraction Techniques A Look At The Latest Technologies And The Companies Involved. ... POSCO stated that it planned to build a large scale lithium processing plant in Argentina, which ...

Sep 11, 2019· Chinese lithium miner Tianqi, one of the world''s top producers of the white metal, has shelved plans to complete a A300 million (205m) second phase expansion at the world''s largest lithium ...

Tianqi Lithium Industries Inc, which controls a majority stake in the Greenbushes mine, the world''s premier producer of lithium concentrate from spodumene, is building a downstream processing plant for lithium hydroxide in Kwinana, 38 km south of Perth. The 12 million order will be delivered by the end of .

In July, LIT announced that it had performed a continuous miniplant run, processing lithium from micas present at one of its upstream projects. The miniplant was run over 15 days, which included prefill, continuous operation, and decommissioning. A total of 229kg of mica ore was processed in that time, with 111 hours of continuous leaching.

Feb 15, 2012· Lithium occurs in a number of pegmatitic minerals, but due to its solubility in ocean water and is commonly obtained from brines and clays. The total lithium content of seawater is very large and is estimated as 230 billion tonnes. Lithium ore beneficiation process. Low grade Lithium ore isn''t suitable for final applications.

Lithium mineral concentrates consumed, in the glass industry or as a preproduct for the production of lithium carbonate, are traded at lithium contents of wt% or wt% Li 2 O depending upon the application. For regular ore deposits with head feed concentrations of 1020% spodumene (% Li 2 O) concentration factors of four to eight are required.

Processing a spodumene ore to obtain lithium concentrates for ... This work describes a study conducted on the processing of a spodumene ore occurring as aplite —pegmatitic lodes in granites located in Northern Portugal, in.

%. Due to its high lithium content, spodumene is considered the most important lithium ore mineral. A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene). Higher grade concentrates with % Li 2 O and low iron content are

Lithium chemical processing capabilities are key to capturing higher margins for lithium producers. Lithium producers capable of developing processing capabilities could be in a position to secure ...

WhatsApp)

WhatsApp)