ballmills micron particle size YouTube

May 24, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

May 24, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

types of grinding mills (Table 1). Some devices, such as ball mills, are more suitable for coarse materials. These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes. Attrition mills are more appropriate for "midrange" size .

Disk Mills are specifically designed for the size reduction for materials in the medium particle size range. The ideal material types for this instrument are hardbrittle and mediumhard. Special. The vibrating cup mill is ideal for the rapid preparation of samples down to .

Particle size distribution influences the physical and chemical properties of solids. Therefore this criterion is of highest importance in the context of science and quality control. Only if the size distribution remains constant, a steady product quality can be guaranteed, as the following examples show:

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help.

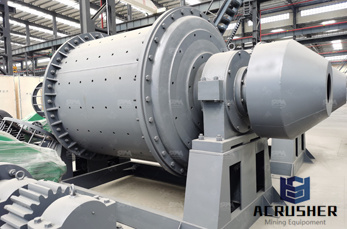

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

Table 2: Mill Comparison of Media Size, Power Intensity, number of grinding media ... Grind Product P80 microns Net Energy kWh/t Ball Mill IsaMill. the particle. But for a 9 micron particle this rim is sufficient for the mineral to disintegrate (Figure 2).

Mar 09, 2016· Materials are exposed to a wide set of processing and technology applications to control chaos, instill order, and ultimately create an engineered powder. One of powder''s more dominate physical attributes is Particle Size Distribution (PSD) characteristics. Particle size and shape play an important role in the performance of any powder.

18. Can you use different sizes of balls in a ball mill to simulate size distribution from roll refiner? Different sizes of balls in oneball mill will not work. You can have different ball mills refining different fineness and, by mixing these, mimicking bimodal particle distribution.

This single unit is capable of milling materials up to a hardness of 10 Mohs and enables accurate and highly controllable particle sizes to be achieved, typically with narrow size distribution. A range of mill sizes is available for throughputs ranging typically from to 2 tonne per hour with average particle sizes as low as 1 to 2 microns.

The small and average capacity Ball mills are used for the final grinding of drugs or for grinding suspensions. The maximum capacity Ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals. Advantages of Ball Mills It produces very fine powder (particle size less than or equal to 10 microns).

Bill Henry, executive VP at Jet Pulverizer (Moorstown, NJ), notes that ball and jet mills have traditionally been used to reduce particle sizes down to just below 1 micron, normally the uppersize domain limit for all things "nanotech." "That''s the focus for these mills, particularly for electronics and battery applications," says Mr ...

FRITSCH ONE STEP EAD. FRITSCH is an internationally respected manufacturer of applicationoriented laboratory instruments. Our instruments have been used for decades worldwide for Sample Preparation and Particle Sizing in industry and research laboratories.

Solid Particles and Particle Size. Ceutics Exam 2. STUDY. PLAY. T/F. The rate of dissolution of solids increases as surface area increases. ... 1 micron. Particle size reduction equipment. Ball mill Micronizer. Ball mills. Grinders consisting of rotating cylindrical container that can be used to grind solid materials into fine powders Must ...

Attritors is approximately 50% smaller than that obtained from conventional ball mills and about ... micron particles with the Attritor is much shorter. ... The research determined yeast derived beta 1/3,1/6 glucan sourced from this ... to maintain a size of 12 microns, a particle size much smaller than globular or ... As a glucan re ...

I have mineral wollastonite within average particle size of D50 = 3 micrometer, I am trying to decrease the particle size to nano scale, using a planetary ball milling, I hope I can understand the ...

Ball Mill . Nov 18, 2008Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls) put in the shell, and has a simple structure and ease of handling. Furthermore, The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wet 14.

This highefficiency mill produces submicron size particles. Powder particle processing Industries. Industries. ... a combination of a vertical agitated ball mill and a high performance air classifier represents a further milestone on our way. ... Adjustable particle size: Fineness is determined by changing the classifier speed.

Jun 19, 2019· Onlin Service : This Channel Have Equipments Working Video : https:// the influence of mill ...

5 micron ball mills manufacturer Cameroon DBM Crusher. ball mills micron particle size Grinding Mill China. 5 micron ball mills for sale. Can planetary ball mill grind particles to the size smaller than 0 The mixer/mill can grind powder to particle size below micron by adding suitable milling .

Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantages. Key properties of grinding media are size, density, hardness, and composition. Size: The smaller the media particles, the smaller the particle size of the final product.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

How to decrease particle size of alumina powder with ball milling? ... powder and I want to decrease its particle size down to 1520 micron with ball milling. ... I applied ball mill for 24 hour ...

Contaminationfree milling to reduce particle size is a considerable process challenge. AVEKA Solution: AVEKA responded to the customer''s needs by using a proprietary ball milling process that uses a specially cleaned and conditioned ball mill with a ceramic lining in conjunction with high purity, high hardness ceramic media.

WhatsApp)

WhatsApp)